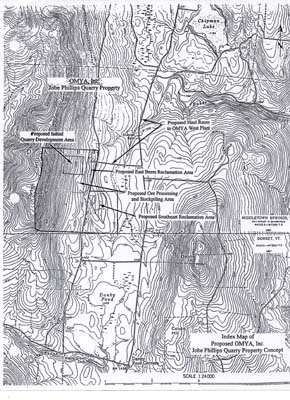

OMYA. INC.

JOBE PHILLIPS OUARRY PROPERTY

DANBY, VERMONT

QUARRY PLAN WITH PROGRESSIVE RECLAMATION

Geology Department

Pluess-Staufer Industries, Inc.

Proctor, Vermont

January, 2000

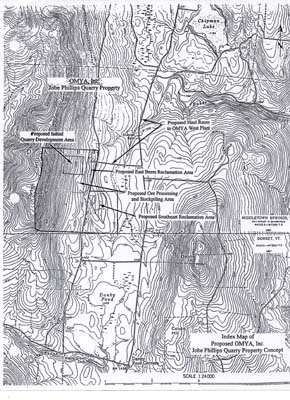

OMYA. INC.

JOBE PHILLIPS OUARRY PROPERTY

DANBY, VERMONT

QUARRY PLAN WITH PROGRESSIVE RECLAMATION

Geology Department

Pluess-Staufer Industries, Inc.

Proctor, Vermont

January, 2000

Introduction

OMYA, Inc.'s Jobe Phillips Quarry property is located in Danby, Vermont, approximately twenty three miles south of the existing OMYA West Plant in Florence, Vermont, in which white, high-calcium marble ore is processed into fillers and extenders for the paper, plastic and paint industries. Plant feed (crushed marble ore) for the OMYA West Plant currently consists of carefully blended ore from Middlebury Ouarry in Middlebury, Hogback Quarry in Pittsford and South Wallingford Quarry in South Wallingford. It is the purpose of the proposed project to provide an additional source of plant feed for the ongoing operation of the OMYA West plant.

Geologic mapping and core drilling of the Jobe Phillips property has determined a unique and substantial proven reserve of economically recoverable white to light-grey, high-calcium marble ore. The high-grade ore located on the Jobe Phillips property will provide a suitable feed stone capable of being blended with other ore from other developed sources of plant feed for the OMYA West plant.

The proposed quarry area initially to be developed is situated around two existing quarry prospects that are not presently in use. The development of the quarry area will involve the progressive removal of glacial till overburden from the underlying marble bedrock. The glacial till will be used to create land forms (berm and reclamation area) to the east of the quarry area. The quarried marble ore will be processed, sized and stockpiled on site as plant feed. Once stockpiled, blended plant feed will be hauled by truck via Town roads and State highways for delivery to the OMYA West Plant for further processing.

Description

The Jobe Phillips property is located on the east slope of Dutch Hill in the northern part of Danby, Vermont. The property consists of approximately 400 acres and is a mixture of moderately sloped, woodland and pastureland. Otis Road (Blood Street) runs along the east side of the north half of the property and runs through and divides the south half (Breton Farm) of the property.

The marble layers that will be quarried are geologically associated with the Columbian member of the Shelburne Formation. Marble ore associated with the Columbian member of the Shelburne Formation also currently is being quarried at Middlebury Quarry, Hogback Quarry, and South Wallingford Quarry for the OMYA West Plant. The folded and thickened marble layers as exposed on the Jobe Phillips property strike north-south, average approximately 1000' in width, and have an apparent westerly dip into the hillside. The marble ore layers are bounded to the west by blue-grey dolomitic marble associated with the Bascom Formation and are bounded to the east by grey dolomite associated with the Intermediate Dolomite member of the Shelburne Formation.

The marble ore consists of white to light-grey, high-calcium marble that occurs in distinct horizons within the width of the marble layers. Associated with the marble ore are grey-green schistose beds and light-grey to grey marble layers that will have to be carefully blended or selected out as waste rock in the quarrying process. Waste rock will be utilized for the construction of interior haul roads and in the reclamation process. The waste rock material also could be made available to neighboring towns and local contractors for use as road aggregate and rip-rap.

The Jobe Phillips property has been core drilled in order to determine the quality and reserves of the proposed quarry development area. Twenty three diamond drilled core holes totaling 6857' have been drilled cross-sectioning the deposit over a strike length of approxirnately 3200'. The marble layers have been cored down to a depth of approximately 500' below grade. Core samples have been analyzed by the OMYA laboratory for brightness and chemistry. Lab results confirm that the marble ore from Jobe Phillips is suitable for plant feed. With careful quarry selection and blending with other sources, it is anticipated that the Jobe Phillips property could provide an economical source of plant feed to supplement other sources in order to secure continued operation of the OMYA West Plant.

PLAN OF OPERATIONS

Overall Ouarry Development Concept

The proposed quarry development area is located at the northern end of the Jobe Phillips Quarrv property on a moderately sloped, partially wooded hillside and measures approximately 1000' north-south by 1000' east-west. The western half of the proposed quarry development area is generally open land and consists of exposed marble bedrock outcrops with little associated overburden whereas the eastern half of the proposed quarry area is generally wooded (deciduous hardwoods) and covered with no bedrock exposure. The upper western section (exposed surface top lift) of the proposed quarry development area will be progressively quarried to provide rock for the construction of internal access roads and the pad for the ore processing and stockpiling area. In conjunction with the initial quarrying of the upper exposed quarry levels to the west, overburden below and to the east will be removed progressively to expose marble ore bedrock and will be utilized in the construction of the proposed east berm reclamation area that will assist in screening the quarry operation.

Quarry development will progress from north to south and west (top) to east (bottom). As overburden is removed from west to east, the existing wooded area to the east also will be cleared progressively from west to east maintaining the existing natural tree screen to the east and south for an extended period.

Quarrying of the upper top lift benches initially will involve establishing the uppermost quarry bench by driving an approximately 100' wide keyway at the north end of the proposed quarry area to the west up to an approximate bench height of 50' and then quarrying an approximately 200' wide quarry face to the south. Following the removal of the upper most top lift quarry bench, another 100' wide keyway established from the next quarry bench level below the initial keyway location will be driven to the west to within approximately 20' of the previously established western quarry face above providing a safety bench. Once the second (lower) keyway has been established to the west quarry limit, the approximately 200' wide second lift quarry face will be quarried south. As the second lift is quarried to the south, quarry excavation and quarry haul truck loading operations on that quarry bench level will be screened by the remaining bedrock slope to the east. As the second lift keyway progresses ahead to the south, the remaining bedrock slope will be progressively "daylighted" to the east from north to south behind the screened south advancing second lift. The lower quarry bench levels below will be developed in a similar manner in order to continue screening the quarry operations to the greatest extent practicable. Once the upper quarry benches have been developed and removed, all quarrying activities will be down within the established open quarry area and completely screened from view. At that time, only the upper section of the west quarry face will be visible from off site. and, over time, the exposed quarry face will weather to a dark-grey color, blending with the surrounding background of the wooded slope above.

Overburden Removal and Placement

Removal of glacial till overburden will be required to expose the marble bedrock for quarrying particularly in the lower eastern half of the proposed quarry area. Depth of overburden has been determined with the use of an air-track drill. Drilling was conducted on east-west lines across the deposit at intervals of 400' with drill holes approximately 100' apart. Each hole was drilled through glacial till overburden to bedrock, recording the depth, and then drilled at least 10' further into the marble bedrock to confirm the presence of marble ledge versus loose boulders. Air-track drilling indicates the presence of approximately 425,000 yd3 in-place (bank cubic yards) of overburden over the proposed initial quarry development area. A swell factor of 25% is used for the glacial till overburden to estimate approximately 530,000 yd3 of material from that area to be used for the construction of the east berm and southeast reclamation areas.

A 33 acre area, approximately 1,200' long (north-south) by 1200' wide (east-west) encompassing the proposed initial quarry development area, will be cleared progressively of trees and brush prior to the removal of overburden. Any recoverable topsoil will be removed separately from the underlying glacial till and will be used in the progressive reclamation process. Once removed, the glacial till overburden will be placed in one of the two proposed land forms located to the east and southeast of the proposed quarry development area.

Quarrying

The initial quarry development will involve quarrying the area surrounding the two inactive marble quarry prospects measuring 1000' long (north-south) and 1000' wide (east-west). The quarry will be developed in 30' high lifts with safety benches, 20'wide, left in place every two lifts in accordance with federal mine safety requirements. Once developed, the main open quarry access-ramp (10% grade) will be located and decline northerly along the east side of the quarry development area on the dolomite foot wall layers.

The quarrying process will require drilling and blasting to break the rock to a manageable size for primary crushing and screening. A track-mounted pneumatic drill with a dust suppression device (wet drilling or dust collector) will be utilized to drill the blast holes. It is anticipated that blasting will be performed generally three times per week by licensed and qualified contract personnel. Each blast will be carefully controlled to insure the quality of the ore (quarry selection) and will yield up to approximately 10,000 tons of blasted rock. The use of explosives is controlled by the Mine Safety and Health Administration of the federal government. Each blast will be monitored with a seismograph for ground vibration (peak particle velocity), which will not exceed 0.5 ips on the property line of any adjacent property owner, well below the 2.0 ips recommended margin. Operating hours are anticipated to be from 7:00 AM to 6:00 PM six days per week with blasting conducted between 10:00 AM and 4:00 PM Monday through Friday as required. It is anticipated that, outside of truck loading and hauling of feed stone to the OMYA West plant, Saturday activities typically will involve only maintenance of on site equipment. General quarry operations on Saturdays will be occasional and only as required in order to make up for lost time from significant equipment breakdowns or extended periods of inclement weather or other events beyond OMYA's control.

Blasted ore at the quarry face will be carefully selected with a front-end bucket loader that will load the ore into 35 ton off-road haul trucks. The loaded ore will be hauled out of the quarry area to the onsite ore processing area where it will be crushed, screened and stockpiled for plant feed.

Ore Processing

Ore processing on the Jobe Phillips Ouarrv property will be required to size quarry-run ore into plant feed. Currently, the OMYA West Plant requires -12" and -3'/2" plant feed (that is, ore with a size of less than 12" and 3 1/2", respectively). It is anticipated that the same size feed will be prepared from the ore quarried from the Jobe Phillips Quarry property.

The proposed ore processing area will be located south of the proposed initial quarry development area. A crushing and screening plant will be installed to process the ore. It is anticipated that the installation will consist of a hopper with vibrating feeder supplying a primary jaw crusher producing -12" material, which will be transferred via a belt conveyor to several storage hopper bins. A multi-deck screen and secondary roller cone or impact crusher will be included to produce the -3 l/2" plant feed. A bin truck will haul crushed ore, loaded from the storage bins, to the proposed stockpile area located south of the crushing and screening plant.

Fugitive particulate matter will be controlled with the use of water fed spray jets and/or dust collectors at transfer points in the processing system. (An air pollution control permit will be obtained for applicable regulated activities at the site.) Water will be obtained from surface water sources retained in detention ponds. There are no plans at this time to drill wells to supply water to the operation.

Hauline

Plant feed will consist of a careful blend of crushed ore from various stockpiles in the ore processing area. The blended plant feed will be loaded and hauled by 18-wheel dump trailers (76,000 lb. gross weight - 5 axles) along an internal haul road to be constructed along the west side of Blood Street at the base of the east slope of the proposed east berm reclamation area to a point near the intersection of Blood Street and Hoisington Cross Road. The existing hedgerow along the west side of Blood Street will be maintained to help screen the internal haul road.

Trucks hauling plant feed to the OMYA West plant in Florence will exit the Jobe Phillips Quarry property crossing Blood Street, head east on Hoisington Cross Road, turn north onto East (Tinmouth) Road and proceed to State Highway #140. The proposed route from that point would involve turning east and proceeding to Wallingford, then north on U.S. Route 7 through Rutland and Pittsford to the Florence truck route accessing the OMYA West Plant. Trucks entering the OMYA West Plant will be weighed on existing scales and proceed to unload in the existing plant feed bin or surge stockpiles. It is anticipated that no more than 40 round trips per day, six days per week will be required to haul plant feed from the proposed Jobe Phillips Quarry to the OMYA West Plant.

Progressive Reclamation

Progressive reclamation of the Jobe Phillips Quarry property, which has been utilized successfully at other, similar sites, will involve the creation of two plateau-shaped landforms. The two landforms will be built (i) using glacial till overburden removed from the marble bedrock during the quarry development process and (ii) using waste rock (naturally occurring surface stained marble, schistose beds, and off-color marble unacceptable 6r plant feed) from quarrying.

The proposed east berm reclamation area will be located between the proposed quarry development area and the ore processing/stockpiling area to the west and Blood Street to the east and will be constructed in conjunction with quarry development. The landform will consist of an approximately 2000' long north-south trending berm which will help screen (sight and sound) the quarrying and ore processing operations from off-site. Finished slopes will be no steeper than 3: 1.

The proposed southeast reclamation area will be located southeast of the proposed quarry development area and east of Blood Street on gently to moderately sloped open land and woodland and will be built after the east berm reclamation area is completed. The landform will consist of a relatively flat plateau bounded by a moderate slope to the east. Finished slopes will be no steeper than 3:1. Topsoil from the existing open area to be covered by the proposed landform will be removed and placed on the top of the gently sloping landform surface as the southeast reclamation area is constructed. An additional five acres of productive farm land will be gained (net increase) on the east side of Blood Street once the southeast reclamation area is completed.

The two proposed reclamation areas will accommodate the placement of approximately 1,500,000 yd3 of material. As stated the two reclamation areas will be developed progressively in conjunction with the development of the quarry. Where practical, any topsoil encountered in the removal of overburden will be segregated and used to top-dress the surface of the landforms. Finished slopes will be seeded with conservation mix, limed, fertilized, and mulched for stability and erosion control. The ridgeline of the proposed east reclamation area will be planted with evergreen trees to increase the screening from the berm. The relatively flat plateau area of the proposed southeast reclamation area will be suitable for planting and harvesting of agricultural crops as other, similar areas have been used.

Once quarry operations cease on the Jobe Phillips Quarry property, the reclamation areas will be managed for agricultural purposes, timber production, wildlife habitat or other appropriate use. The quarry area will naturally fill up with ground and surface water once quarry operations end. If the water eventually rises high enough to overflow, the water will be conveyed naturally to the southeast through ditches, existing drainage and settling ponds to Baker Brook. The reclaimed, water-filled quarry area will be a valuable water resource for water supply, recreation, or wildlife habitat.